Every year when Cross Country ends, I find myself in a strange position. All of a sudden, six straight months of intense training and competition are over and I'm left with an abundance of free time. It usually takes a week or so to get out of the "GO GO GO!" mood that creeps in during a long season, but once that's taken care of I catch the bug like nothing else. I first started building computers around this time Sophomore year, and last year I took on a 250-hour science fair project (see 'The Liquid Nitrogen Experiment'). This year, I'm being even more ambitious. Here are a few likely projects for this winter:

I4 Go-Kart:

Normally I'm not a four cylinder kind of guy, but when a friend suggested that we build a go-kart, my first thought was how great a high-revving, mid-mounted four cylinder could be on a modified kart. It'll take loads of work, but the end result should be something to see. I want to join the Formula SAE team at whichever college I attend next year, so this project would give me some invaluable experience. It's also Mario approved.

I've been thinking about this one for a long time. The plan is to buy a window air conditioning unit and modify it to run as an auto-cascade. Auto-cascades take all the benefits of multi-stage cooling systems and leave their problems behind; with the one exception being complexity. Though this makes it the perfect long-term project, it also makes it somewhat unlikely. The cost of all of the tools and materials would run upwards of $700, and the end product would be too expensive to run continuously. I've been researching alternate means of reaching cryogenic temperatures via sound waves, magnets and lasers, but though these options may be more effective in the long term, they are all but impossible to create with my limited resources and know-how.

New Computer Builds:

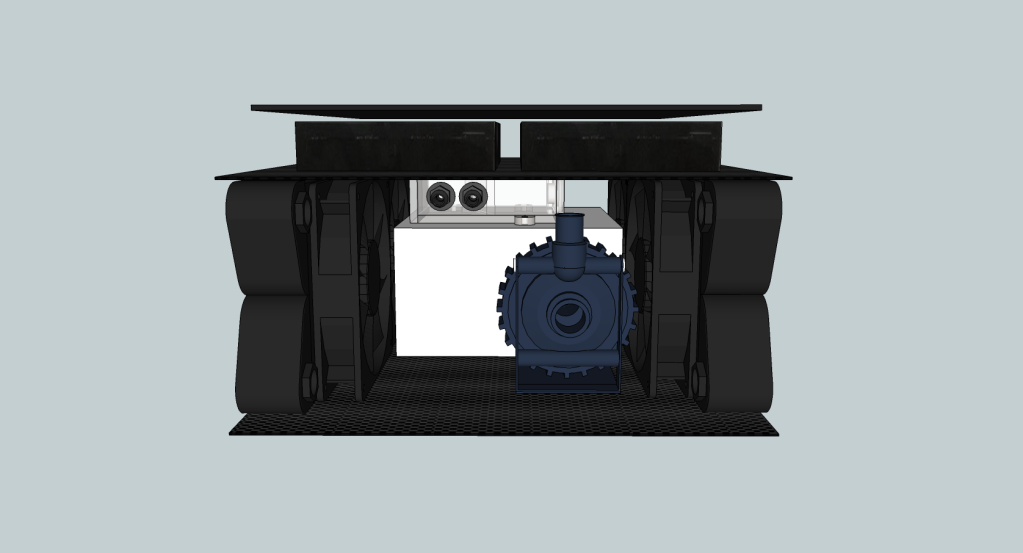

Perhaps the most likely project for this winter is a new computer case. I'll be doing a full re-build for college this summer and I want a new case to go along with it. I've been working on a few different designs, the best of which are posted below. The 3-tiered case is 6.7" x 6.7" excluding the curves, and the larger case is 11" x 12". They will both be made out of carbon fiber. Here's the kicker: the smaller computer has the potential to be just as powerful as the larger one, minus the liquid cooling.